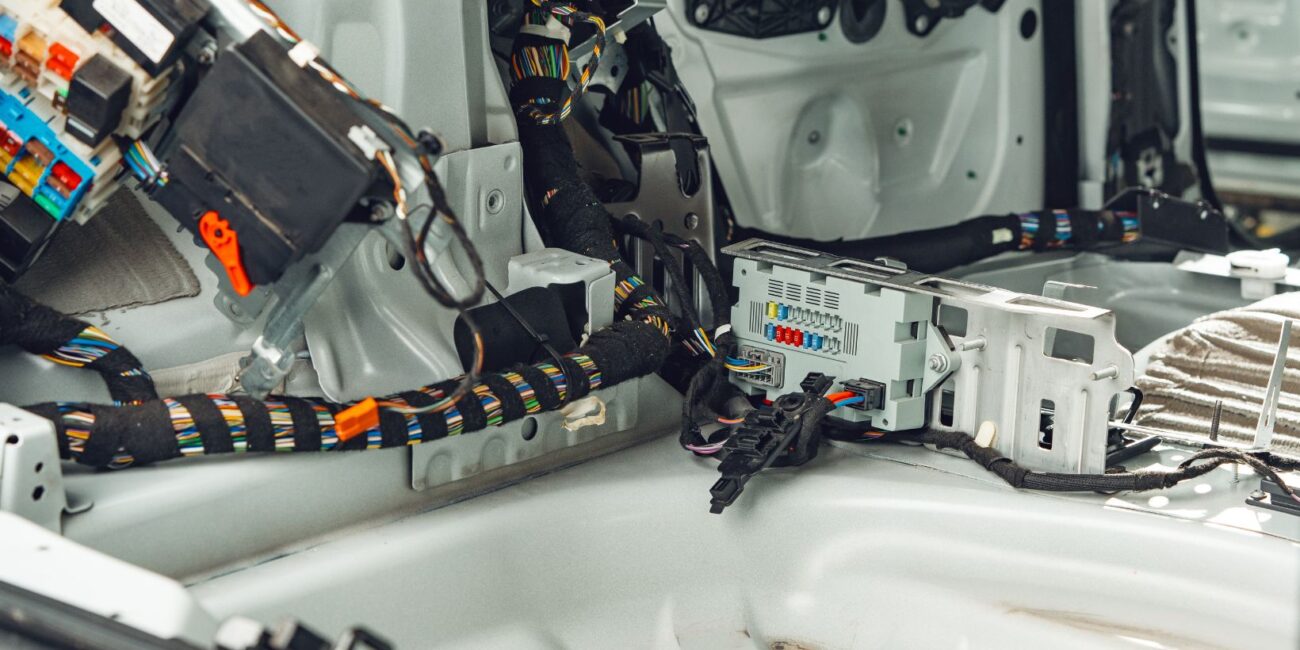

The Importance of Proper Wiring in Off-Road Vehicles

When it comes to off-road vehicles, the electrical system is a critical component that often gets overlooked. The harsh conditions and demanding environments encountered on the trail can wreak havoc on the factory wiring, leading to a host of issues such as intermittent electrical failures, blown fuses, and even complete system breakdowns. Upgrading the wiring in your 4×4 is an essential step in ensuring the reliability and longevity of your vehicle’s electrical system, enabling it to withstand the rigors of off-road adventures.

One of the primary challenges faced by stock electrical systems in off-road vehicles is the increased demand for power. As you add more accessories, such as lighting, winches, and auxiliary electronics, the strain on the factory wiring can become overwhelming. Thinner, less capable wiring can overheat, leading to voltage drops, resistance issues, and even the potential for fire hazards. By upgrading to heavier-gauge, high-quality wiring, you can ensure that your electrical system has the capacity to handle the increased power demands, reducing the risk of failures and providing a more reliable power distribution throughout your vehicle.

In addition to the increased power requirements, off-road environments also subject the wiring to a variety of harsh conditions, including mud, water, vibration, and extreme temperatures. Factory wiring, designed for on-road use, may not be adequately protected against these challenges, leading to corrosion, chafing, and insulation damage. Upgrading to weatherproof, abrasion-resistant wiring solutions, such as marine-grade or automotive-specific cables, can help shield your electrical system from the elements and prevent costly failures down the line.

Implementing Effective Wiring Upgrades

Selecting the Right Wire Gauge

When embarking on a wiring upgrade project for your 4×4, it’s essential to take a comprehensive approach to ensure the longevity and reliability of your electrical system. This involves not only upgrading the wiring itself but also implementing additional protective measures, such as fuse blocks, relays, and circuit breakers.

One of the key steps in a successful wiring upgrade is the use of properly sized and rated wiring. This means selecting wire gauges that can handle the current demands of your electrical system, with a margin of safety to accommodate future expansion. Utilizing a wiring diagram or consulting with an experienced off-road mechanic can help you determine the appropriate wire sizes for your specific vehicle and its electrical needs.

Protecting the Wiring Harness

In addition to the proper wire gauge, it’s crucial to ensure that the wiring is routed and secured in a way that protects it from the harsh off-road environment. This includes using protective loom or conduit to shield the wires from abrasion, as well as securing the wiring harness to the vehicle’s structure using high-quality, corrosion-resistant fasteners. By eliminating potential points of failure, you can significantly reduce the risk of electrical issues during your adventures.

Incorporating Fuse Blocks and Circuit Breakers

Another important aspect of a comprehensive wiring upgrade is the integration of fuse blocks and circuit breakers. These devices act as a safeguard for your electrical system, protecting against short circuits, overloads, and other potentially catastrophic failures. By placing fuse blocks and breakers at strategic points in your wiring harness, you can ensure that any electrical issues are contained and isolated, preventing them from cascading through the entire system.

Utilizing Relays for High-Current Loads

Finally, it’s worth considering the use of relays in your wiring upgrade. Relays can help manage high-current loads, such as those required by winches, air compressors, and other high-draw accessories. By using relays, you can reduce the strain on your vehicle’s factory wiring and ensure that your electrical system is operating at peak efficiency, even under the most demanding conditions.

By taking the time to properly plan and execute a wiring upgrade for your 4×4, you can significantly improve the reliability and longevity of your vehicle’s electrical system. From the use of heavy-gauge, weatherproof wiring to the integration of fuse blocks, circuit breakers, and relays, these upgrades can provide the peace of mind you need to tackle any off-road adventure with confidence.

Proper Installation and Testing

Upgrading the wiring in your 4×4 is a significant undertaking, and it’s crucial to ensure that the installation is done correctly. Take the time to plan your wiring layout, label and route the cables neatly, and use the appropriate termination methods, such as heat-shrink butt connectors or high-quality crimps. Additionally, perform thorough testing of your upgraded electrical system to identify and address any potential issues before hitting the trails.

Maintaining Your Upgraded Wiring System

Even with a comprehensive wiring upgrade, it’s essential to maintain your vehicle’s electrical system to ensure it continues to perform reliably. Regularly inspect the wiring for any signs of wear or damage, such as chafing, corrosion, or loose connections. Address any issues promptly to prevent them from escalating into larger problems. Additionally, consider incorporating periodic maintenance tasks, such as checking fuse and circuit breaker operation, into your off-road vehicle’s maintenance routine.